Environment

Climate Action

Policies and Our Approach

Pursuing a Net-Zero Carbon Society

As the impact of climate change on water resources and agricultural yields poses serious risks for the stable supply of beverage products, Suntory Beverage & Food (“the Company”) recognizes climate change as an important issue for business continuity. As such, the Company and its group companies are united in taking initiatives to fight climate change. Our goal is to reduce environmental impact across the entire value chain, so that our efforts make impacts smaller or even eliminate them altogether, by collaborating with the environmental efforts governments and local municipalities are taking to mitigate global warming.

Endorsement of Task Force on Climate-related Financial Disclosures (TCFD) Recommendations

Suntory Beverage & Food has declared its endorsement of the recommendations of the Task Force on Climate-related Financial Disclosures (TCFD*), which was established by the Financial Stability Board (FSB). In addition, we have conducted scenario analysis for climate change according to the recommendations of the TCFD and studied the risk that climate change may have a significant impact on the crops we use as ingredients in our products. Going forward, we will conduct a more advanced scenario analysis and expand disclosure of information related to the risks and opportunities that climate change poses to our business.

-

*The Task Force on Climate-related Financial Disclosures

Initiatives

SBT Initiative Certification

Suntory Beverage & Food has signed the "Business Ambition for 1.5°C", a campaign led by the Science Based Targets initiative *1 in partnership with the UN Global Compact and the We Mean Business *2 coalition to hold global temperature increases to 1.5°C above pre-industrial levels.

Suntory Benerage & Food has had its 2030 emissions reduction targets approved by the Science Based Targets initiative as consistent with levels required to meet the goals of the Paris Agreement.

-

*1The SBTi is a partnership between CDP, the United Nations Global Compact, World Resources Institute (WRI) and the World Wide Fund for Nature (WWF). It drives ambitious climate action in the private sector by enabling companies to set science-based emissions reduction targets.

-

*2We Mean Business is a global nonprofit coalition working with the world's most influential businesses to take action on climate change. Together they catalyze business leadership to drive policy ambition and accelerate the transition to a zero-carbon economy.

Implementation Structure

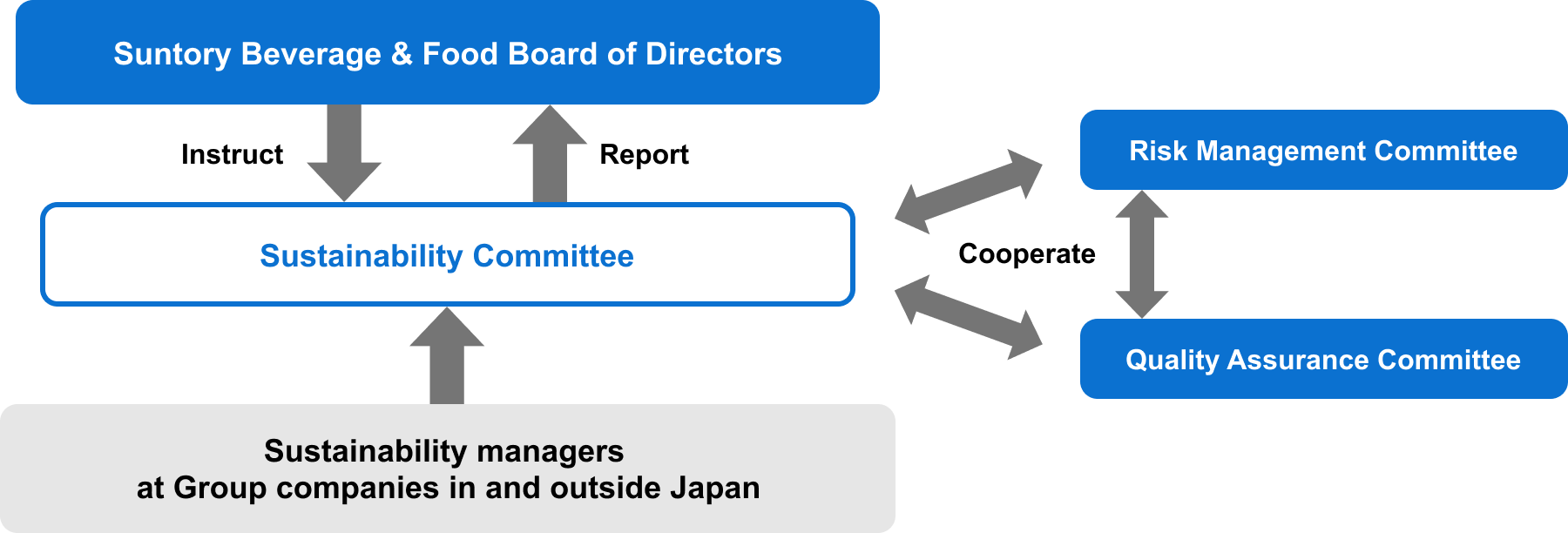

Environmental Management Structure

To promote sustainability management, the Sustainability Committee acts as an advisory committee to the Company’s Board of Directors. The sustainability strategies and the progress on priority themes (water, greenhouse gases, containers and packaging, raw ingredients, health, human rights and enriching life) are discussed by the Sustainability Committee under the lead of the Chief Sustainability Officer. The progress of environmental and social activities as well as business risks and opportunities are reported to the Board of Directors twice a year. In addition, the Board of Directors is provided with the opportunities to hear advice from third-party experts on sustainability management.

Suntory Beverage & Food’s sustainability management promotion organization

Targets and Progress

Targets and Progress at Suntory Beverage & Food (GHG)

Climate Change Measures

- Aim for net zero greenhouse gas emissions across the whole value chain by 2050

Continue to promote energy conservation, proactively implement renewable energy solutions, utilize next-generation infrastructure options and work together with stakeholders across the value chain in order to contribute to realizing a decarbonized society

Environmental Targets toward 2030

Greenhouse gas (GHG)

- Reduce GHG emissions from our direct operations*1 by 50%*2

- Reduce GHG emissions across our entire value chain by 30%*2

FY2023 Results

- Reduced GHG emissions at our sites*1 by 22% (compared to FY2019)

- Reduced GHG emissions across our value chain by 14% (compared to FY2019)

-

*1Suntory Beverage & Food plants that manufacture finished products.

-

*2Based on emissions in 2019.

Internal carbon price

Employing internal carbon pricing

The Company introduced internal carbon pricing in 2021, using an internal carbon price of 8,000 JPY/ton. This measure is widely used in management decisions, mainly when making investment decisions on facilities that will contribute to the fight against climate change. The Company plans to invest a total of approximately 100 billion JPY by 2030 in pursuit of the shift away from carbon. These initiatives are expected to reduce greenhouse gas (GHG) emissions by approximately 1 million tons compared to a business-as-usual projection for 2030.

Our Initiatives

Initiatives toward a zero carbon society

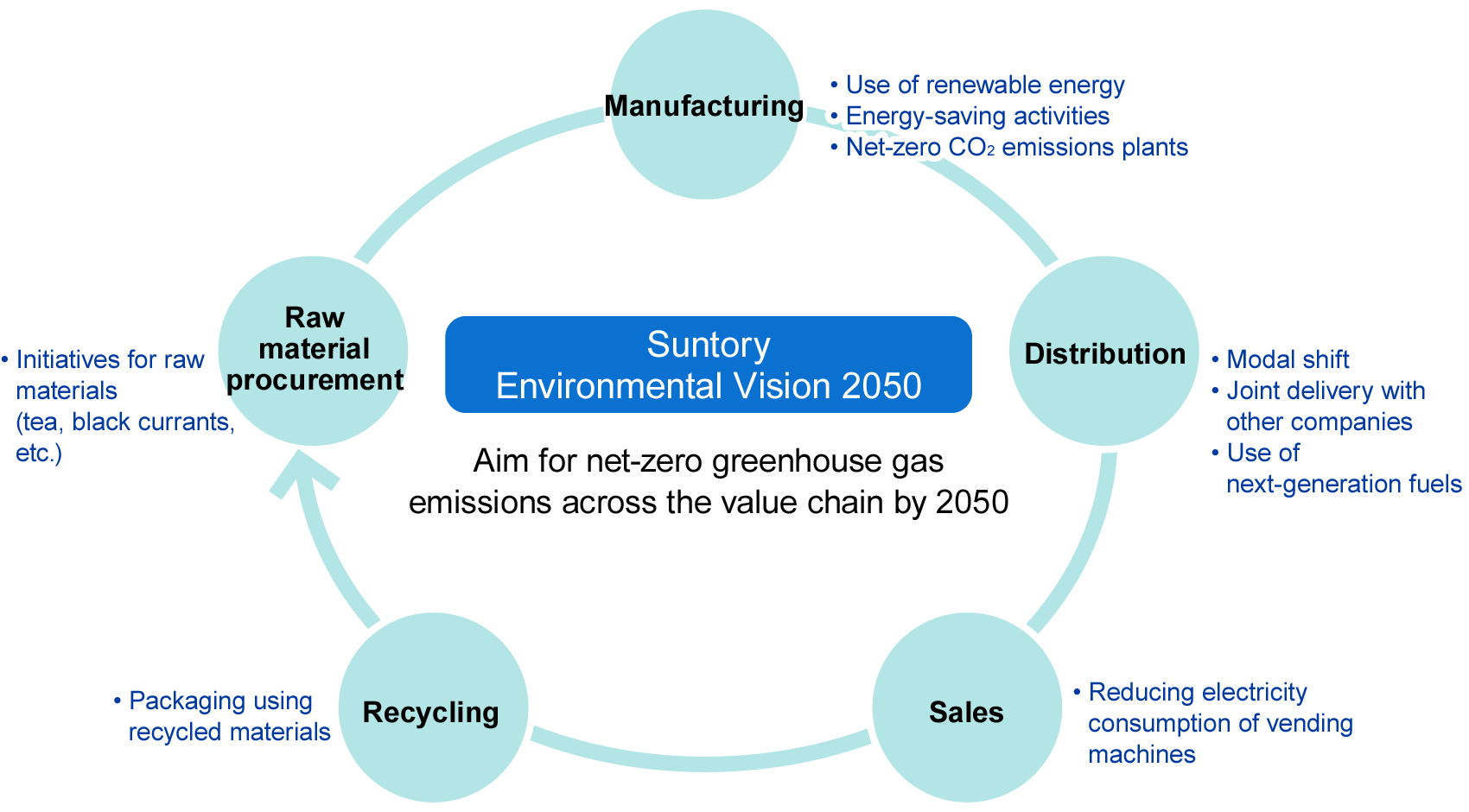

Aiming for net-zero greenhouse gas emissions across the value chain by 2050, we are taking steps to fight climate change across the entire value chain, from raw material procurement and manufacturing to distribution and sales.

Suntory Environmental Vision toward 2050/Environmental Targets toward 2030

Initiatives toward a zero carbon society

Initiatives in Raw Ingredients and Procurement

Initiatives in Raw Ingredients

Suntory Beverage & Food is working to mitigate the impact of climate change on its business with respect to raw materials, including green tea and blackcurrant.

Green Tea

To promote sustainable procurement of tea leaves, the raw material for green tea beverages, the Company has launched a long-term initiative in collaboration with tea farming areas. By working with the Kuma Regional Agricultural Cooperative (JA Kuma) to introduce environmentally friendly tea farming processes, we have reduced GHG emissions by over 30%* compared to conventional processes.

In conjunction with the pursuit of high-quality tea production, we hope to go on contributing to stable succession and training of successors in tea farming regions.

-

*GHG emitted per weight unit during the production of green tea material, from raw leaves to rough tea

Blackcurrant

Suntory Beverage & Food Great Britain and Ireland has been conducting research on new, climate change-resistant species of blackcurrant. In July 2020, after years of research in collaboration with the James Hutton Institute, an agricultural research facility, we harvested a new climate change-resistant species, named Ben Lawers.

Initiatives in Production and R&D

Use of Renewable Energy

The Company utilizes 100% renewable energy for electric power purchased at all of its production and research sites in Japan, the Americas, and Europe. In addition to procured power, we are installing solar panels and introducing biomass boilers as required to generate renewable energy at our production sites.

-

Suntory Minami Alps Hakushu Water Plant

-

Suntory Kita Alps Shinano-no-Mori Water Plant

-

Carcaixent Plant (Spain)

-

Biomass boiler

(Suntory Kita Alps Shinano-no-Mori Water Plant)

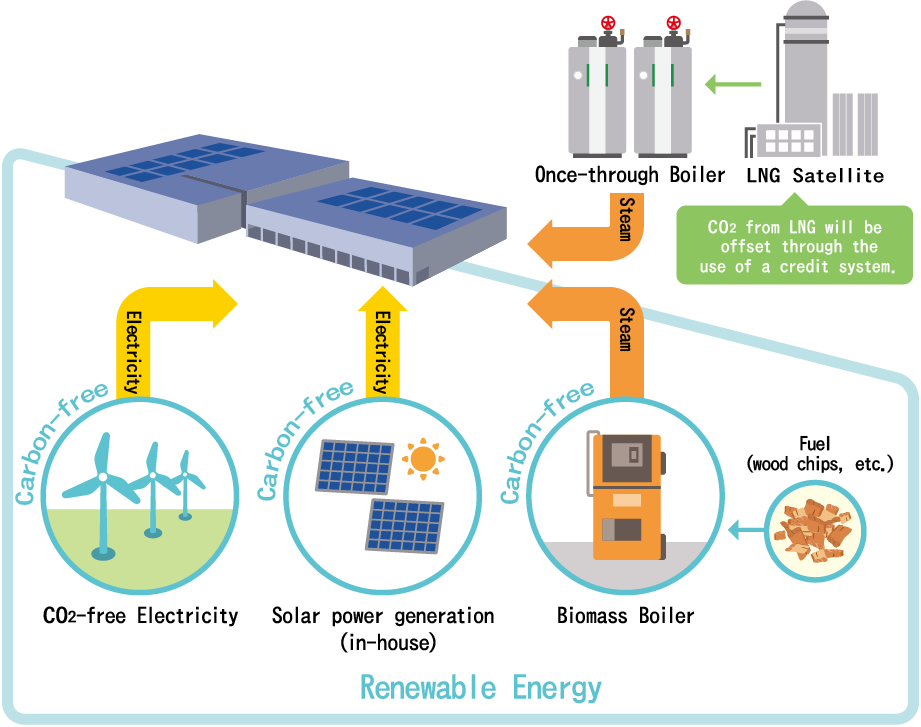

Net-Zero CO2 Emissions Plant

Suntory Group’s first net-zero CO2 Emissions plant in Japan

The Kita Alps Shinano-no-Mori Water Plant (Omachi City, Nagano Prefecture) which started operation in May 2021 as a fourth water source for Suntory Tennensui Mineral Water, become the Suntory Group’s first net-zero CO2 Emissions plant in Japan through adoption of solar power generation facility and boilers which use biomass fuel, electric power procurement derived from renewable energy as well as offsetting.

In June 2023, the Kita Alps Shinano-no-Mori Water Plant has been proved to be a carbon-neutral facility after receiving a PAS2060*1 verification from the British Standards Institution (BSI). This is the first verification received by a food & beverage factory in Japan.

-

*1Abbreviation for Publicly Available Specification 2060, an international standard issued by BSI to quantify, reduce, and carbon offset greenhouse gas (GHG) emissions from products/services/activities, thereby declaring them neutral (i.e., emissions of GHGs are effectively zero).

System for Achieving Zero CO2 Emissions at Suntory Kita Alps Shinano-no-Mori Water Plant

PAS 2060 Qualifying Explanatory Statement(Japanese Only)

Investment in CO2 Reduction (Decarbonization)

The Suntory Group, which includes Suntory Beverage & Food, plans to invest a total of approximately 100 billion yen by 2030 to promote decarbonization. The Group estimates that this investment will deliver a reduction of approximately 1 million tons of greenhouse gas (GHG) emissions in its direct operations compared to a business-as-usual projection for 2030.

Initiatives in Logistics

CO2 reduction through logistics efficiency improvements

The Suntory Group, is working to reduce the environmental impact of its logistics operations, including transport and delivery operations and warehouse operations. The Group is working to shorten transport and delivery distances traveled from plants to customers by promoting local production for local consumption, maximizing utilization of large vehicle load capacity, and switching to next-generation fuels and transport modes with lower GHG emission levels. In warehouse operations, the Group is working to shorten operating hours and reduce power consumption.

During 2022, sales (KL) expanded by 7% over the previous year. GHG emissions rose 9% to 150,000 CO2-tons* while the basic unit was 22.7 CO2-ton/thousand KL sold.

-

*Due to a supply/demand mismatch caused by extremely high summer temperatures, transportation distances and frequency of travel increased.

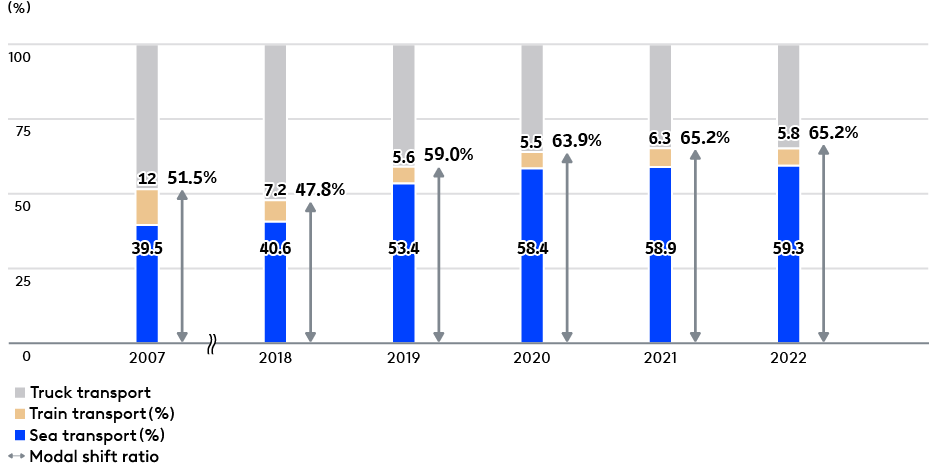

Enhancing the modal shift rate

The Suntory Group, including the Company, is pursuing a modal shift to rail and ocean transport, which emits less GHG than trucks. The 2022 modal shift rate rose over the previous year.

Enhancing the modal shift rate

Enhancing usage of fuels with less GHG emissions

To encourage our transportation partners to use next-generation fuels that emit less GHGs than conventional fuels, we identified issues for expanded use in the future and are engaged in discussions for solving those issues. In 2022, a total of four companies used renewable fuels.

Collaborative Efforts with Logistics Affiliates

Seeking to further reduce environmental impact, certifications have been acquired by 201 of the Suntory Group’s logistics affiliates (as of 2021), including ISO14001 (52 sites) and Eco Stage (23 sites) as well as Green Management advocated by the Ministry of Land, Infrastructure, Transport and Tourism. In addition, in response to amendments to the Rationalization in Energy Use Law, the Suntory Group collected GHG emissions data such as the monthly distance driven by vehicles, the amount of fuel consumed, and the useful load of logistics affiliates.

Collaborative Efforts with Other Companies

The Suntory Group is partnering with other companies to reduce environmental impact in logistics by practicing joint distribution and shared use of transport containers.

| Coordination | Description | Starting from | Results |

|---|---|---|---|

| NISSIN FOODS HOLDINGS CO., LTD. | Joint transport in the Obihiro area of Hokkaido | June 2017 | Approximate annual GHG reduction of 50 tons (Total figures for both companies) |

| Four major beer companies in Japan | Joint distribution in some areas of Hokkaido (Kushiro/Nemuro) | September 2017 | Reduction of approximately 330 tons of GHG emissions per year (*Figures apply to all four beer companies) |

| Four major beer companies in Japan | Joint distribution for transport between Kansai/Chugoku area and Kyushu area | April 2018 | Reduction of approximately 1,500 tons of GHG emissions per year (*Figures apply to all four beer companies) |

| Four major beer companies in Japan | Joint collection of beer pallets | November 2018 | Reduction of approximately 4778 tons of GHG emissions per year (*Figures apply to all four beer companies) |

| Unicharm Corporation | Joint use of railway containers between Shizuoka area and Fukuoka area | February 2021 | Reduction of approximately 2 tons of GHG emissions per year (*Total figures for both companies) |

| Daio Logistics Co., Ltd. | Joint Kanto-Kansai transport | August 2022 | Approximate annual GHG reduction of 115 tons (*Two-company total) |

| Daio Logistics Co., Ltd. | Parties share one-way rail containers | August 2022 | Approximate annual GHG reduction of 100 tons |

| Daio Logistics Co., Ltd. | Railroad Container Round-trip Utilization between Kanto and Shikoku | June 2023 | Approximate annual GHG reduction of 31 tons |

| Japan Freight Liner Company | Utilization of ocean 40ft containers for return trips | July 2023 | Approximate annual GHG reduction of 89 tons |

Initiatives in Sales

Energy Conservation in Vending Machines

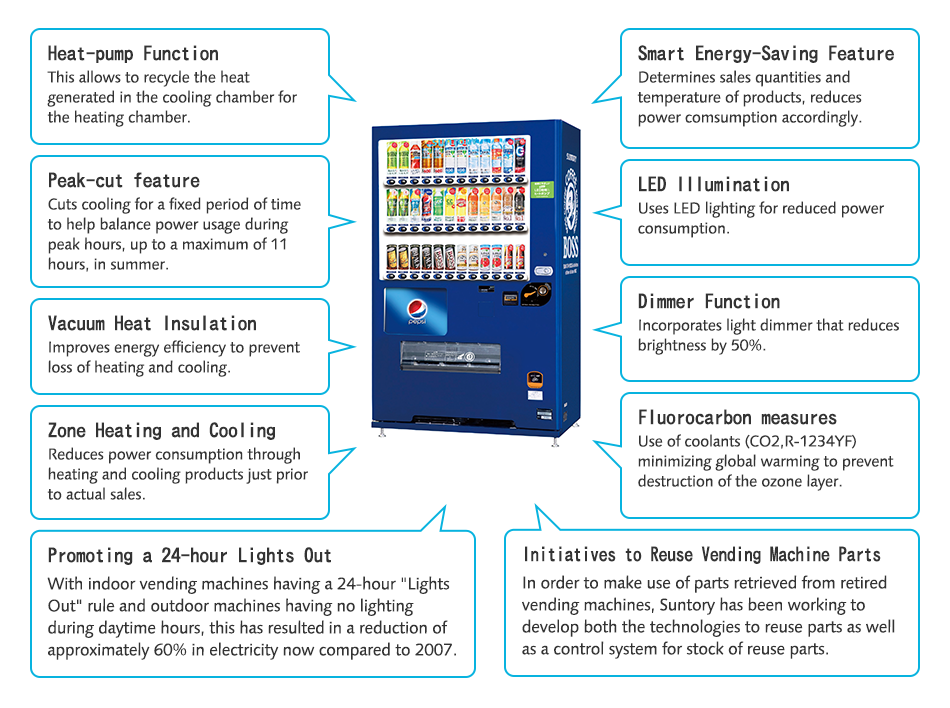

Suntory Beverage & Food is implementing various initiatives to save energy in vending machines in Japan as one of its priority initiatives to reduce GHG emissions across the entire value chain.

Key Features of Suntory Vending Machines

The Company is implementing various initiatives to save energy in vending machines in Japan as one of its priority initiatives to reduce GHG emissions across the entire value chain.

Key Features of Suntory Vending Machine

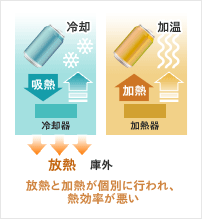

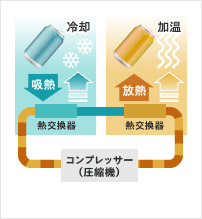

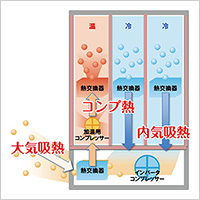

What is a heat-pump vending machine?

A heat-pump vending machine in Japan is a vending machine with a built in system to collect heat generated by the cooling chamber for the heating chamber. These vending machines largely contribute to energy saving through function to effectively use heat inside the vending machine and latest machine can even exchange heat with the atmosphere.

-

Vending machines prior to heat-pump type

-

Heat-pump vending machine

Reducing Energy Consumption of Vending Machines

Since we introduced a peak-cut feature in 1995, we have been striving to introduce vending machines with lower consumption of electricity. Since 2007, we have been promoting installation of heat-pump vending machines that facilitate even more efficient energy usage compared to conventional vending machines as main energy-saving machine. Nearly all of the vending machines put into use in 2010 and all new vending machine (excluding some special-function machines) from 2011 were heat-pump models and also LED lighting were installed to them.

From 2012, we started introducing Hybrid Heat-pump Vending Machines which can reduce electricity consumption by additional 30% compared to normal Heat-pump Vending Machines.

In addition, by fitting refurbished machines*1 with heat-pump equipment, the ratio of heat-pump vending machines against all Suntory vending machines was 87% in the end of 2021.

In 2013, "Mahou VIN Vending Machines"*2 which has a capability of suspending cooling for extended time by to having high refrigerant effect from using vacuum heat insulation materials, etc., in addition to energy saving heat-pump function. This vending machine enables the reduction of both environmental impact and electricity load during the peak hours in summer.

-

*Vending machine that is capable of suspending cooling for extended time due to high refrigerant effect by using vacuum heat insulation materials, etc. Refrigeration is suspended for 8 to 14 hours each day.

Introducing Ultra-Energy-Saving Vending Machines

In April 2014, we began adopting "Ultra-Energy-Saving Vending Machines" (Eco Active Machines) that operate on approximately half the energy consumption (420kWh/year) compared to conventional heat-pump vending machines with the cooperation of machinery manufacturers the use of to further aim to contribute to reducing environmental impact. It stores two compressors, one dedicated to heating and other cooling and uses various latest technologies such as inverter control, vacuum heat insulation materials, electronic expansion valve and LED lighting to control energy consumption to an optimum condition to realize reducing electricity consumption.

-

©Sanden Holdings Corporation

-

Super energy-efficient vending machines

(Eco Active machines)

Promoting a 24-hour Lights Out

To promote reductions in GHG emission and combat global warming, vending machine manufacturers have promoted energy-saving measures since 1991, prior to establishment of the Kyoto Protocol. As a result, during the 15 years leading up to 2005, we achieved an approximate 50% reduction in energy consumption per vending machine. The industry also agreed to aim for a further 37% reduction by 2012, in comparison to 2005 figures, with indoor vending machines having a 24-hour "Lights Out" rule and outdoor machines having no lighting during daytime hours*. The industry met its goal in 2011.

-

*Reduces about 10% of power usage by turning off the lights during the day time, about 20% by 24 hours

Photo of vending machine

Measures Against Chlorofluorocarbon

Controlled chlorofluorocarbons that destroy the ozone layer are not used for refrigerants in our vending machines today. New vending machines that are introduced also use no chlorofluorocarbons substitutes that have a large impact on global warming. All of our machines are assumed to be R-1234yf, which has a low global warming potential.

Initiatives to Reuse Vending Machine Parts

We are actively conducting initiatives to realize effective use of resources even in vending machines. We are advancing development of technology toward the reuse of parts as well as management systems for the reuse of parts in order to use vending machine parts that are collected in vending machines again. In 2021, the reuse rate of parts that required repair or maintenance was 58%. We are striving to effectively use resources by expanding the components to reuse parts even further in the future.

Ensuring Reasonable Waste Disposal of Vending Machines

We are leading the industry in building a Vending Machine Waste Disposal System that collects and recycles vending machines to throw away, which we have expanded nationally since January 1997. We are strictly managing disposal from the initial selection of vending machines to discard to the final disposal in compliance with the revisions to the Wastes Disposal and Public Cleansing Act in April 2001. We are properly processing broken machines by understanding the amount of machines to collect based on the Act for Rationalized Use and Proper Management of Fluorocarbons even in regards to the fluorocarbons that are used as a refrigerant in vending machines.

Installation of Vending Machines to Provide Beverages in Emergencies

We are developing and advancing the installation of vending machines to provide beverages in emergencies to contribute to building cities able to combat disasters. Normally, it sells beverages just like a regular vending machine, but in the event of a disaster or other emergency, it provides beverages free of charge. Beverages can be easily accessed even if the power goes out. Many people used this system after the Great East Japan Earthquake that struck in March of 2011. We are progressing with the installation of these vending machines centered upon public institutions, hospitals, and companies with roughly 25,000 units put in place through the end of 2021 by implementing wire type vending machines that have the benefit of not requiring maintenance in addition to battery-type vending machines. In Japan, we plan to actively introduce these types of vending machines in the future.

Emergency beverage vending machine

Relations with Stakeholders

Climate change policy recommendations to the public sector

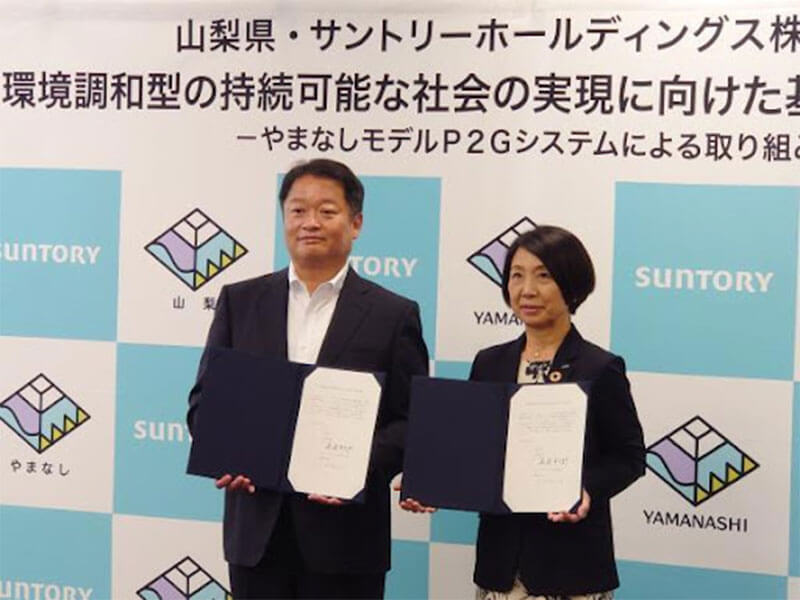

Installing Japan's largest 16-megawatt P2G (Power to Gas) system for in-house green hydrogen production

On September 5, 2022, Suntory Holdings Ltd. signed a basic agreement with Yamanashi Prefecture for realizing an environmentally harmonious and sustainable society. Suntory will collaborate with Yamanashi Prefecture on decarbonizing the Suntory Minami Alps Hakushu Water Plant* and the Suntory Hakushu Distillery by installing the Yamanashi Model Power to Gas (P2G) System at the Hakushu facilities by 2025. This will constitute Japan's largest green hydrogen production system, and does not emit any greenhouse gas (GHG). The green hydrogen produced will not only be used as fuel for heat energy at the company’s Hakushu facilities, but are also planned to be utilized in the surrounding communities.

-

*Suntory Beverage & Food-owned plant

Governor Kotaro Nagasaki (Yamanashi Prefecture) and then-Managing Executive Officer Makiko Ono (Suntory Holdings) (2022)

Raising awareness of heat stroke prevention to combat global warming impact

The Suntory Group is working to combat the impact of global warming by raising awareness at elementary schools and companies about ways to prevent heat stroke with the rising temperatures. This initiative include the free provision of posters and leaflets (total of 14.1million copies distributed as of June 2022) to raise awareness about preventing heat stroke created together with The Education Newspaper to elementary schools throughout Japan and the support of heat stroke measures at each school. We are also linking to other activities to raise awareness about heat stroke by manufacturing and selling GREEN DAKARA which is recommended as a countermeasure to heat exhaustion*1.

-

*1The Ministry of Health, Labour, and Welfare recommends 40-80mg of sodium per 100ml as a countermeasure to heat exhaustion.