Jun. 22, 2017

For a sustainable world: Working to create a factory in harmony with the environment

Our business is providing the blessings of the nature. At the factories, we are involved in various activities to reduce our environmental impact, such as the effective use of energy in the production process and the reduction of byproducts and waste products.

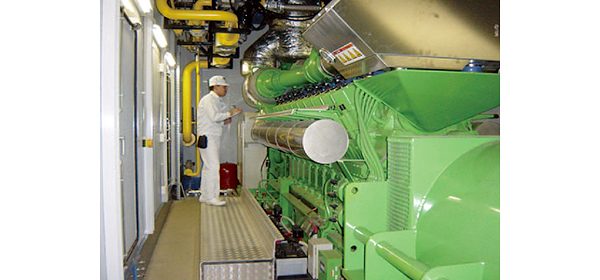

Saving energy

We are using cogeneration system in our production activities. Through recovering the heat from in-house power generation and using it as a partial heat source for beer mashing and coffee and tea extraction, this system has increased 70-80% of our energy efficiency and reduced 20-30% of our CO2 emissions. Up till end of April 2016, the system is in use at four of our domestic plants, Suntory Products Ltd. Haruna Plant, Suntory Beer Ltd. Tonegawa Brewery and Kyoto Brewery, and Suntory Spirits Ltd. Osaka Plant.

Natural Energy: Using Snow/Ice Thermal Energy

As an example of the use of natural energy, at Iwanohara Vineyard Co. Ltd. (located in a snow belt), we are utilizing the regional feature by the “snow room” built to preserve the winter snows in 1898. Using the thermal energy of the snow, natural energy helped control the fermentation of the wine and the temperature of the storehouse. The snow room was rebuilt in 2005, and it is still used to cool the wine cask storage. We have also installed the snow room at Suntory Products Ltd. Okudaisen Bunanomori Water Plant, using it to handle some of the spring cold energy load.

Maintaining a 100% Recycling Rate

At the Suntory Group’s domestic factories, we are working to reduce the emission of byproducts and waste products created in the production process, and to keep a 100% recycling rate. In 2016, our domestic factories produced a total of 244,604 tons of byproducts/waste products, which meant 1.0% reduction from the previous year’s total, and 2.2% reduction per unit production*. We also succeeded to maintain 100% recycling rate.

* Usage rate per production kℓ