No.14688

2024/10/28

- CSR

Suntory Introduces World’s First(*1) Commercialized PET Bottles Using Bio-Paraxylene

Download PDF

Tokyo, Japan (October 28, 2024) — Starting this November, Suntory Group will begin introducing PET bottles using paraxylene derived from used cooking oil (bio-paraxylene) for select products in Japan. This will be the world’s first*1 commercialized PET bottles using bio-paraxylene*2 and will help significantly reduce CO2 emissions compared to those made from conventional virgin petroleum-based materials. The group will introduce this to approximately 45 million beverage PET bottles*3 with consideration underway to expand its use across its product portfolio.

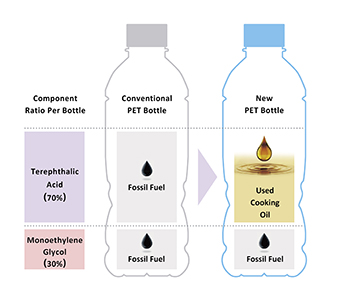

PET resin, the raw material for PET bottles, consists of 30% monoethylene glycol (MEG) and 70% terephthalic acid (TPA). Since 2013, Suntory Group has been using plant-derived materials*4 for MEG in its Suntory Tennensui brand PET bottles. In this new challenge, the group has succeeded in producing TPA at a commercial scale by using paraxylene derived from used cooking oil, a biomass resource.

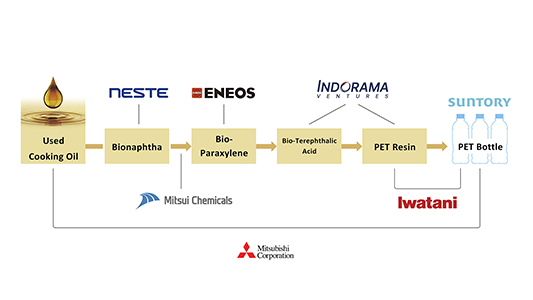

To achieve this, the group established a global supply chain in collaboration with corporations such as ENEOS Corporation and Mitsubishi Corporation to procure bionaphtha derived from used cooking oil and ultimately produce PET bottles. Bionaphtha can be produced from the manufacturing process of sustainable aviation fuel (SAF), among other things, and as SAF production is expected to increase, the importance of developing a bio-naphtha supply chain is also growing. Suntory Group aims to build a more robust mass production system for bio-based PET bottles in cooperation with stakeholders.

Role of each stakeholder in this project

| Mitsubishi Corporation | Manage entire supply chain |

| Neste | Produce bionaphtha from used cooking oil |

| Mitsui Chemicals, Inc. | Produce intermediate material of bio-paraxylene using bionaphtha |

| ENEOS Corporation | Produce bio-paraxylene from intermediate material using mass balance approach*2 |

| Indorama Ventures | Produce PET resin by reacting MEG with TPA produced with bio-paraxylene |

| Iwatani Corporation | Manage operation from production to delivery of PET resin |

| Suntory Group | Form PET resin into PET bottles for its products |

In September 2023, Suntory Holdings announced its collaboration with ENEOS Corporation for the collection of used cooking oil in Japan. Suntory Group is also considering taking advantage of this collaboration to make bio-based PET bottles using bio-naphtha domestically produced at ENEOS Corporation's SAF plant which plans to start its operations after 2027. (See News Release No.14454).

As a corporation sustained by the gifts of nature and water, and with a purpose to inspire the brilliance of life, by creating rich experiences for people, in harmony with nature, Suntory Group has been committed to achieving a sustainable society since its founding.

Based on the Suntory Group Plastic Policy established in 2019, the group aims to use only recycled or bio-based material for all its PET bottles used globally by 2030 and eliminate the use of virgin petroleum-based materials. To achieve this goal, the group has been working on reducing weight of PET bottles, caps and labels based on the group’s 2R+B (Reduce/Recycle + Bio) strategy for about 20 years. The group has also been promoting "bottle-to-bottle" horizontal recycling*5 in Japan through agreements with over 100 municipalities and more than 40 companies and actively introducing recycled PET bottles in its products. As of 2023, more than half*6 of its soft drink bottles sold in Japan use 100% recycled PET bottles. Through various initiatives, Suntory Group will continue its efforts to achieve a circular and carbon-neutral society.

Learn more about Suntory Group’s Sustainability Vision here and about its work on sustainable packaging here.

*1 As of October 28, 2024. Based on research by ENEOS Corporation and Mitsubishi Corporation.

*2 Mass balance approach applied. Under the mass balance approach, for a product manufactured by mixing a material that has a specific characteristic with those without that characteristic, the characteristic can be allocated to a part of the output of the product in proportion to the amount of the material with the characteristic used in the production process.

*3 280ml and 285ml size PET bottles.

*4 Materials derived from waste molasses that do not impact the food chain.

*5 Recycling used PET bottles into new PET bottles.

*6 By quantity.

About Suntory Group

As a global leader in the beverage industry, Suntory Group aims to inspire the brilliance of life, by creating rich experiences for people, in harmony with nature. Sustained by the gifts of nature and water, the Group offers a uniquely diverse portfolio of products, from award-winning Japanese whiskies Yamazaki and Hibiki, iconic American whiskies Jim Beam and Maker's Mark, canned ready-to-drink -196, The Premium Malt’s beer, Japanese wine Tomi, and the world-famous Château Lagrange. Its brand collection also includes non-alcoholic favorites Orangina, Lucozade, Oasis, BOSS coffee, Suntory Tennensui water, TEA+ Oolong Tea, and V energy drink, as well as popular health and wellness product Sesamin EX.

Founded as a family-owned business in 1899 in Osaka, Japan, Suntory Group has grown into a global company operating throughout the Americas, Europe, Africa, Asia and Oceania, with an annual revenue (excluding excise taxes) of $20.9 billion in 2023. Its 41,511 employees worldwide draw upon the unique blend of Japanese artisanship and global tastes to explore new product categories and markets.

For more information, visit www.suntory.com and Drink Smart.

|

|